As we have seen in the Introductory Course to SAP S/4 HANA PP, depending on the type of industry and processes that we need to implement it can be more or less convenient to use a specific functionality in SAP (Production Types)

The process order is an object included in the functionality of SAP S/4 HANA PP-PI, and it is designed for industries like Chemical, Pharma, or Food. Where it is very important the manufacturing processes control and the tracking of materials, either raw materials or finished products, with batches.

One process order is basically a manufacturing order but with some added functionality. In fact, internally they are managed with the same main table and even in some cases they use the same programs for their process.

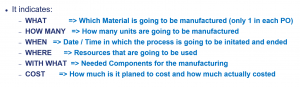

Therefore, mainly, one process order, must answer the same questions that one manufacturing orders.

Process orders are managed internally in SAP with category 40.

- Master Data Maintenance (PLM)

- Sales and Distribution (SD)

- Materials Requirements Planning (MRP)

- Capacity Planning

- Materials Management (MM)

- Logistics

- Handling Unit Management

- Batch Management

- Quality Management (QM)

- Costing

- Logistics Information System or Business Intelligence

- Classification System

The main functions that can be done in a process order are:

- Status management

- Manufacturing through the use of different production versions

- Scheduling

- Capacity requirements determination

- Cost calculation

- Batch assignment to the manufactured product

- Coproducts and byproducts manufacturing

- Availability control of raw materials

- Quantity calculation of raw materials

- Active products ingredients management

- Batch determination for raw materials and components

- Resources network

- Resources selection

- Shopfloor papers printing

- Creation of control recipe for process management

- Generation of process instructions (PI Sheets)

- Staging of raw materials and components

- Confirmation of quantities, activities or times

- Goods receipt

- Period close with assignment of process cost, indirect costs, WIP calculation, deviations calculation and order settlement

- Archiving and recovering

- Collective porcess orders management

The most outstanding functionalities added to the discrete manufacturing orders, are the possibility of creating Process Instructions and the Process Management through the use of control recipes.

PROCESS INSTRUCTIONS (PI-SHEET)

SAP PP-PI allows the creation of custom instructions to display on the screen for the operators to check them at the moment of processing each process order. These instructions can be generated in an XML file, so that, they can be displayed in a browser even if SAP GUI is not installed, or even in a tablet.

These instructions can be customized for each recipe we use, so they can be different for each process order. And, apart from displaying information, they can allow the user to enter some data. Thus, for instance, it is possible to peform in them day-to-day activities like consumptions, confirmations, and goods receipts. But they will also allow to enter additional information like different parameters obtained during the manufacturing, parameters that can be important for improving or controlling the quality of the products.

Furthermore, they also allow to perform specific basic calculations that can help users in their activities.

Finally, one functionality very important for some industries, like Pharma, and above all for compliance with the best practices (GMP) is the possibility of using the electronic signing in these PI Sheets. This ensures that the operator in charge of each process order is the one that enters these parameters values to the system.

PROCESS MANAGEMENT WITH CONTROL RECIPES

Due to the requirement of managing data of how the manufacturing process has been performed, it is common the demand of an automatic integration of the different machines and tools used in the shopfloor with the ERP (weighting machines, mixers, ovens, vessels, …).

SAP PP-PI offers a ready-to-use interface for integrating them. It includes a message monitor for evaluating the status of the communication. And, besides that, with the possibility of integrating them with each process order, linking this information with them.

BEST PRACTICES COMPLIANCE (GMP – GOOD MANUFACTURING PRACTICES)

Although GMP compliance is recommended in any industry, it is key in some specific industries like Pharma.

SAP PP-PI provides the following functionalities for this compliance:

- Recipes and inspection plans approval procedure

- Process orders approval procedure

- In-process quality inspections

- Materials identification

- Materials reconciliation of consumptions in each process order

- Electronic batch

- List of where-used batches

- Electronic signature

- Audit trails

OTHER FUNCTIONS

Besides all of these functions, we can also take into account the following ones.

BATCH DERIVATION

It allows transferring the batch characteristics of consumed raw materials to manufactured products. It will allow selecting the material from which to get these characteristics and which of them must be transferred (for instance: the date of manufacturing)

CONFIGURABLE MATERIALS MANUFACTURING

Although not so common, it also allows the use of the variants configurator for building the bill of materials and the manufacturing recipe based on the selected characteristics for the manufacture.

COLLECTIVE ORDERS AT SEVERAL LEVELS

It allows linking vertically different process orders, in a way that makes it easier to manage them together, instead of individually.

Recent Comments