In this lesson we will see the main differences in the Warehouse Structure supported by EWM and the one supported by WM.

WM (Warehouse Management) was during many years the unique available functionality in previous releases of the SAP ERP for managing a warehouse with locations or bins. Currently, there are still many organizationst that use it. The most advanced functionality, nevertheless, and in which SAP will go on working for adding more options is EWM. Notwithstanding it has left a WM version in S/4 HANA for those cases in which less complexity is involved and a leaner solution might be preferred.

In this post we will list the main differences between both solutions.

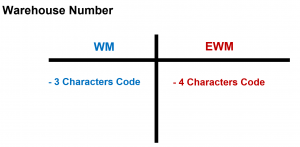

WAREHOUSE NUMBER

The Warehouse Number in EWM will have 4 digits instead of 3, as it has in WM.

Although this can appear as a small change, we must take into account that organizations are becoming more complex and that it is possible that we find companies that can model a high number of warehouses. Or that they want to assign an intelligent coding leaving intermediate entries, for what an additional digit can help a lot.

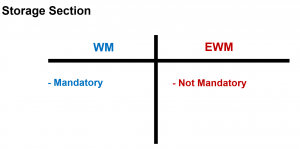

STORAGE SECTION

In WM it is mandatory to maingain at least one Storage Section for each Warehouse Type, while in EWM it is not mandatory.

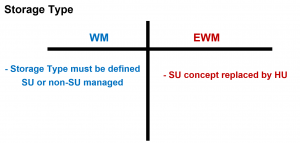

STORAGE UNITS AND HANDLING UNITS

In WM, in the Warehouse Type, we must define if it is managed with Storage Units or not.

The concept of Handling Unit already exists in Inventory Management, the functionality of warehouse management without bins. Basically what it defines is how the Materials are going to be moved in eah Warehouse.

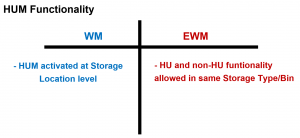

HANDLING UNITS FUNCTIONALITY

In WM, apart from the Storage Units, as we have seen, it is possible to use Handling Units if they are defined in the Inventory Management functionality (without bins).

As in Inventory Management, Handling Units can only be defined at Warehouse level, this is is the unique option for using this functionality.

In EWM, nevertheless, this concept is much more flexible. It allows to combine Materials managed with Handling Units and without them in the same Warehouse Type and even in the same Bin.

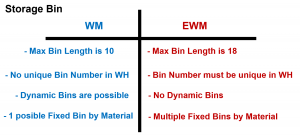

BIN CHANGES IN EWM WITH RESPECT TO WM

The Bin is the main element in both WM and EWM, as it is the one that will allow us to manage where our Materials are stored.

With EWM, the following changes were introduced in this element:

MAXIMUM LENGTH OF THE BIN CODE

While in WM the maximum lenght of the Bin Code is 10 characters, in EWM, we can use up to 18.

Again, this enlargement of this field length will allow more flexibility when intelligently naming the bins (as it is common practice).

UNIQUENESS OF THE BIN CODE

In WM, you can use the same Bin Code in different Warehouse Types. While in EWM, each Bin Code must be unique in the whole Whareouse Number.

Being able to use the same code in different Warehouse Types can give some flexibility, but at the same time it does not allow to completely define a Bin only by its code, as it requires always to add the Whareouse Type in which it is.

Using a unique code, and taking into account that EWM allows ust to use 8 more characters, as we have seen in the previous point, we can immediately identify the bin only by its code.

DYNAMIC BINS IN WM versus EWM

In WM it is possible to use Dynamic Bins, while in EWM it is not possible (this concept does not exist).

Dynamic Bins allow to be created automatically when a movement is executed. In EWM, the destination bin must always be created in advance.

FIXED BIN BY MATERIAL

In WM it is possible to define only one Fixed Bin by Material, while in EWM it is possible to define several ones for the same Material.

Recent Comments