The first step in every Extended Warehouse Management implementation will be the definition of the Warehouse Structure.

Somehow, we need to model in the system the physical locations and movements among them.

A wrong design can create many issues in the future, so it is very important to understand clearly how it can be structured in EWM.

Inventory Management Structure

Even if the objects described in this point do not belong to EWM, it is important to understand them in order to understand the rest of the structure.

Plant

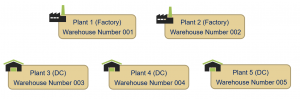

In S/4 HANA, as in the previous releases, the main logistic unit is the Plant.

Each Plant is going to define a different physical location where all logistics activities (planning, procurement, production, distribution, …) are done.

For instance, we can define a different Plant for each Distribution Center, Factory, Third-party Warehouse, …

The Plants are assigned to their respective Company Code.

Storage Location

The next logistical entity will be the Storage Location.

They usually define different areas within the same Plant (within the Factory for instance). But in some cases some of them can be defined for physical locations not in the same place but at some distance (but logistically belonging to that Plant).

Each Storage Location must be created for one, and only one, Plant.

But one Plant can have more than one Storage Location.

For example, normally in a Factory different Storage Locations are defined for the Raw Materials Storage Area, for the Production Area and for the Finished Good Storage Area.

For moving Material quantities among different Plants and among different Storage Locations, it is required to post Material Movements in the Inventory Management functionality. And this functionality can be enough for some Plants with not many Materials/locations.

The Storage Locations will show the Material/Quantities of all the Materials contained in them. But not the specific location where they are within the Storage Location.

In order to manage the stocks at a lower level in the system, defining the exact location where each Material/Quantity is placed and the movements among these locations, it will be needed to use the EWM functionality.

Specially in those places where chaotic warehouse must be used, it is required to implement EWM.

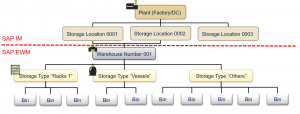

So, what we have seen till now are the Inventory Management Organizational Entities:

EXTENDED WAREHOUSE MANAGEMENT STRUCTURE

Warehouse Number

The highest Organizational Entity to define in EWM is the Warehouse Number.

It will allow to manage an entire physical warehouse or even combine locations from different warehouses not sitting in the same place.

At the same time, this entity is the one that connects the Inventory Management functionality to the EWM one.

At least one Storage Location must be assigned to each Warehouse Number. But more than one Storage Location (even from different Plants) can be assigned to the same Warehouse Number.

Every Storage Location assigned to a Warehouse Number, will be managed in EWM.

That means, that whenever the stock is received in that Storage Location it will be needed to be placed logically in a specific location (Putaway).

And whenever it is moved to another Storage Location or delivered it will be needed to specify the specific location from where it will be removed.

Storage Type

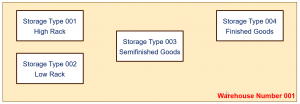

The Storage Types will be defined for each Warehouse Number.

They define different physical areas within the warehouse. But they can also define different nature of storage, type, …

For instance, we can define different Storage Types for Racks, Bulks, Hazardous Substances, …

Storage Bins

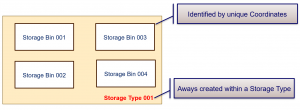

Below the Storage Types, there will be different Bins, each of them defining a specific location where the stock can be placed.

They are the lowest level at which a stock can be found in the system.

A naming convention must be defined in order to identify physically to which location each of them is referring to.

Every time we move one quantity of a Product from a Bin to another Bin, a movement must be done in EWM (as we will see this is done with Warehouse Tasks).

So, it is important to define the required granularity. In a small room with not many Products at a time, it might not be necessary to define more than 1 Bin. As any small movement will require to update it into the system.

Sections and activity areas

In addition to the previous entities, the sections and activity areas allow to group different bins for applying to them specific functionalities.

Sections will only allow to group bins within the same storage type, while activity areas allow to group bins from different storage types within the same warehouse number.

So far, we have seen the following entities:

Recent Comments