INTRODUCTION

Each production operation must be made in one and only one Work Center.

Depending on the production process, Work Centers can be modelled in different ways.

For instance, each one can represent:

- A machine or group of machines

- A production line

- An assembly or packaging workplace

- An employee or group of various employees

- …

Work Center data are used mainly for:

- Capacity → For defining available capacity for production

- Formulas

- Timetable

- Number of employees or machines

- …

- Scheduling → For defining how employed time is going to be calculated

- Formulas

- Setup times

- …

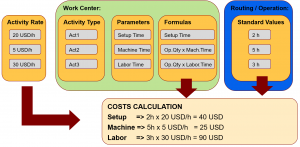

- Costing → For defining how manufacturing cost is going to be calculated

- Formulas

- Cost Center

- Activity Types (for which a rate will be entered)

They will also define:

- Parameters to measure during production execution.

- Some default values which will be copied to the Routing/Production Order.

For example, in order to calculate the cost, the following elements of the Work Center will be used:

ORGANIZATIONAL STRUCTURE

Each Work Center must be defined for only one Plant.

Apart, from that, each Work Center must be assigned to a Work Center Category, which will define the data to be maintain and the usage of it.

MASTER DATA

No previous Master Data is required for the creation of a Work Center.

Some of the Work Center fields must be previously defined in Configuration.

Recent Comments