The first decision to be made when a new S/4 HANA PP implementation is to be done, is to decide which functionality will be used.

S/4 HANA covers a wide a variety of different production types.

From the most repetitive manufacturing process in mass manufacturing, to the custom manufacturing for each different sales order.

For instance, in one extreme, it can be applied to the repetitive assembly during a vendor in the automotive industry (with only of few finished goods always manufactured in the same way).

Or in the other, to the assembly of a custom product, like a ship. Where from finished good to finished good many materials and operations are different from one sales order to the next one.

It can also be applied to industries which need to manage liquids and all the functionality relevant to this kind of manufacturing (batch management, documentation, safety, …). For instance, in the chemical, pharma or food industries.

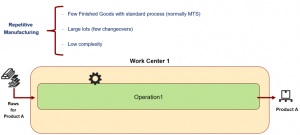

REPETITIVE MANUFACTURING

In those cases where only a few of different finished goods are manufactured in a repetitive way, there are some functionalities which will allow to reduce to a minimum the required steps in the system.

It might be that a line is running the assembly of a product against stock (MTS – Manufacturing to Stock) during various days in a row.

We don’t want to create different process orders and going to the hassle of managing them. So, a specific functionality for this is provided by SAP.

At the end, only the declaration of quantities produced is required.

We even can avoid the requirement of declaration of consumption of components using the functionality of backflushing (automatic consumption when the confirmation is done).

Or even the goods receipt can be done automatically as well with the confirmation.

For instance, it is typical in the assembly of motherboards, where lines specifically setup for each of them are in place and they are running for days with no more input that the number of assemblied boards.

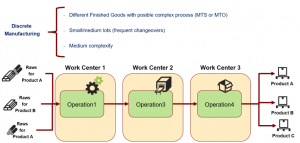

DISCRETE MANUFACTURING

This is the most common type.

It is designed to those cases where different products can be manufactured in the same line, so it is needed to specify in detail what is going to be produced, with which materials (BOM), and how (routing).

In case that it is possible to manufacture the same product in different ways, production versions can be used for specifying how to produce it.

Production orders will be used for containing all of this information and for collecting all the different costs.

They will be released before starting, shopfloor papers can be printed and materials movements and confirmations will all be recorded with reference to those production orders.

For instance, in the assembly of bikes, we can have different models and decide to assembly them in different lots grouped in production orders.

The manufacturing can be against stock or against specific sales orders.

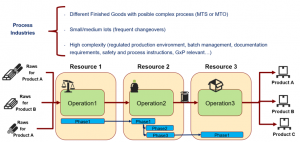

PROCESS INDUSTRIES

Process orders can be used instead of production orders for some specific industries.

Specially in those cases where additional functionality related to the management of liquids is required (recipe management, process control, …), the Process Industries functionality can help to implement all the requirements.

Process orders will work in a similar way than production orders, but with additional functionality.

For instance, operations will be further divided into phases, allowing the functionality required for chemical or pharma processes.

Further approval functionality for master recipes will also cover some of the requirements of these industries.

Through a standard interface it will also facilitate the connection to external machines, which is very important for controlling the different parameters in the productive process in theses industries.

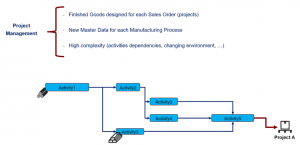

PROJECT MANAGEMENT MANUFACTURING

For the extreme case in which each new product to be sold is complex and must be designed specifically for each sales order, a different functionality is provided.

Project Management functionality will allow to create specifically the different steps, schedule them at the right time depending on dependences, and collect all the different incurred costs.

Due to its complexity, this type of production is not covered for the normal production MTO (Make-to-Order), and will be managed with the Project Management functionality.

Recent Comments