WHAT ARE THE DIFFERENCES BETWEEN PRODUCT AND MATERIAL MASTER IN SAP S/4 HANA?

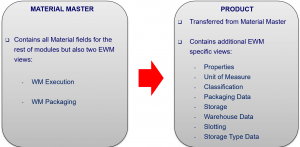

Even if both Material Master and Product represent the same physical entity (each raw material, component, semifinished or finished good), they are different objects in SAP S/4 HANA and with different purposes.

The Material Master is a very important piece of master data for the core functionality. It is a shared master data where we can maintain parameters of different functionalities or departments (finance, purchasing, manufacturing, quality, warehouse, …).

Historically, as new modules were incorporated into the core, new tabs were added with the required fields for supporting these new functionalities.

But with the introduction of SAP APO, an external SAP application with solutions for advanced planning and warehouse management (EWM), it was decided to include the Material Master new required fields for these functionalities in a specific “Material Master” in this piece of software, and they called it “Product”.

As there was an equivalence between the Material Master of the ERP and the Product of the APO solutions, they refer to the same physical material, SAP provided an interface (called CIF) for transferring basic data (from ERP to APO).

But the required fields for APO not included in the Material Master, were updated directly in the Product.

With SAP S/4 HANA, the EWM functionality, formerly in the APO solution, was included in the core. But the concept of Product remained as it was. The only difference is that now that interface (CIF) is not required (at least not for the Material Master fields).

So basically, in the Material Master, we can maintain the parameters of the core modules and some of the ones related to the warehouse management, while in the Product we maintain only specific parameters of EWM.

WHICH VIEWS OF THE MATERIAL MASTER ARE RELEVANT FOR EWM?

There are two views in the Material Master where some EWM parameters must be maintained:

- WM Execution

- In this view, we enter

- Some general parameters of how the operations will be performed in the warehouse for this material, like how to handle the material, storage conditions, if it requires a serial number, …

- Some fields related to Quality Management.

- The possibility of using a parallel Unit of Measure (useful when there is not a fixed relation between two alternative units of measure for the same material).

- For using this functionality we also need to enter the parallel Unit of Measure in the Additional Data segment of the Material Master.

- In this view, we enter

- WM Packaging

- In this view, we enter

- Some general parameters indicating how this material must be packed.

- The maximum possible dimensions for packaging this material.

- In this view, we enter

The parameters maintained in these two views will be, therefore, transferred automatically to the corresponding Product in EWM. Some of the additional data such as Units of Measure and GTINs/EANs data will be also transferred.

If we don’t create these two views for a material, we won’t be able to use it in EWM.

The reason why these parameters are maintained in the Material Master instead of in the Product, is that they need to be accessed by other core functionality of the ERP.

WHICH ARE THE VIEWS WE CAN MAINTAIN ON THE PRODUCT?

On the EWM Product (transaction code /SCWM/MAT1) we can maintain the following views:

- Properties

- General properties that apply to all the locations where a Product is managed in EWM.

- Unit of Measure

- Units of measure will be imported from the Material Master, so they cannot be changed in the Product.

- Additional GTINs/EANs

- Also imported from the Material Master. It will allow to specify how the Product is coded.

- Classification

- Also imported from the Material Master. It allows to add some custom characteristics only required for each organization.

- Packaging Data

- It specifies with some additional fields to the Material Master ones how we can pack this Product.

- Storage

- It also imports some fields from the Material Master, but it allows to enter additional ones for setting up how the Product will be managed in the Warehouse.

- Warehouse Data

- It contains data only available in the Product and it allows to set up how the Product is going to be placed and putaway from the different bins.

- Slotting

- It allows to maintain parameters for the slotting functionality. This functionality will allow to optimize the the space and efficiency in the warehouse.

- Storage Type Data

- Data for this Product when used in a specific Storage Type

Recent Comments