Apart from the main organizational units seen in the previous point, there are some important additional ones used for different functionalities.

Warehouse layout

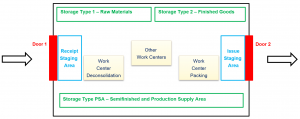

In order to understand better these additional objects, let’s see a typical warehouse layout for a factory or warehouse:

The typical flow of materials would be from left to right.

First of all, materials received in our plant must enter through a door.

Normally, they will remain in a receipt area till they are unpacked (if necessary), checked and placed in a bin (putaway).

They will be used then in production processes or just remain in their bin till they are needed.

Finally, when they need to be delivered, the stock removal process will take place.

They will be packed if needed and placed in the issue staging area till they are delivered through a door.

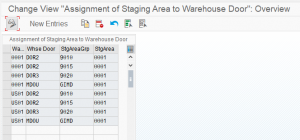

Staging area

The staging area represents in EWM the space near the warehouse door for temporary storage of products.

It will be assigned to a specific door:

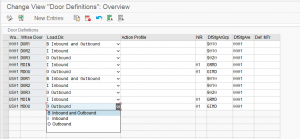

Doors

The doors are locations within the warehouse through which the materials enter or exit.

It is and organizational unit.

Multiple doors can be defined for each warehouse:

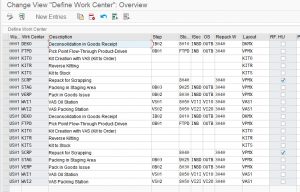

Work centres

The work centres in EWM represent locations where some warehouse activities are done.

Some of these activities can be:

- Packing

- Deconsolidation

- Quality inspection

- Counting

- Packing

- Value-added services (VAS)

Recent Comments